Parylene Coating

The ultimate solution for protecting sensitive components from harsh conditions.

Deposition Room

The journey begins here, where components are prepared and inspected for coating.

Plasma Cleaning

Surface contaminants are eliminated to ensure uniform adhesion of the Parylene coating.

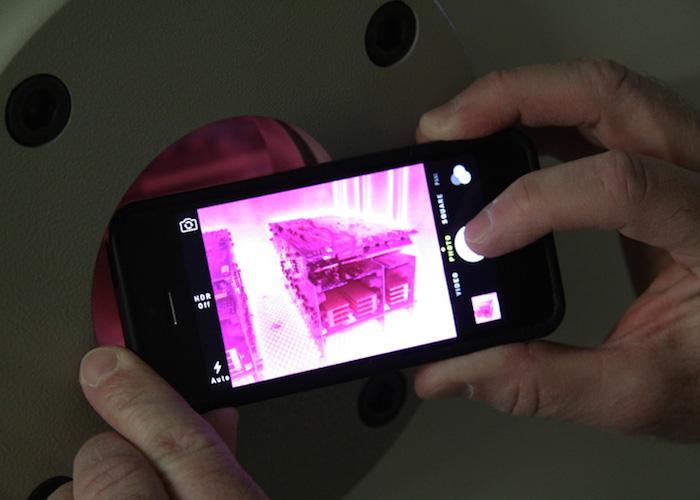

A Look Inside

Precision engineering at work, ensuring every component is ready for the next step.

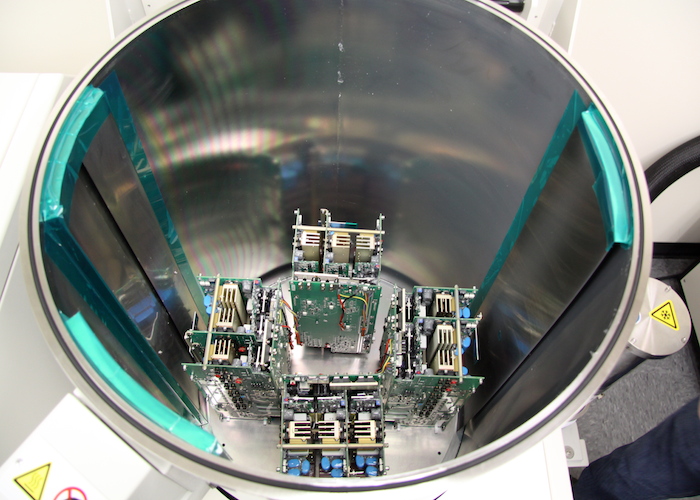

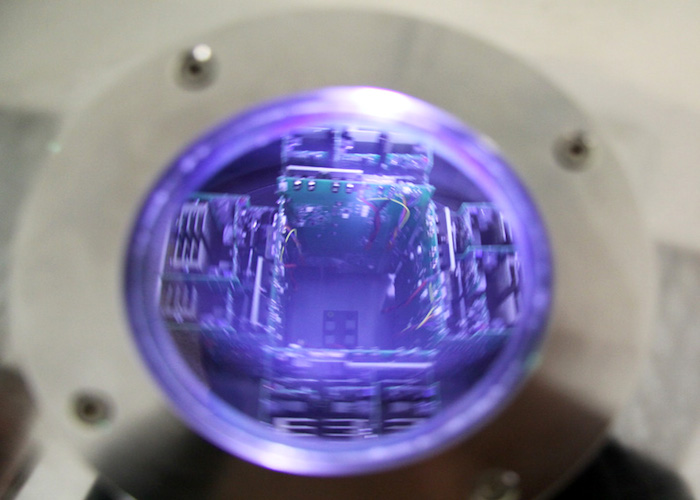

Parylene Deposition System

The heart of the process where the vapor deposition creates a seamless protective layer.

Deposition Tank

Components enter a vacuum chamber, ensuring even coating across all surfaces.

Coating in Process

A meticulous process that guarantees long-lasting durability and reliability.

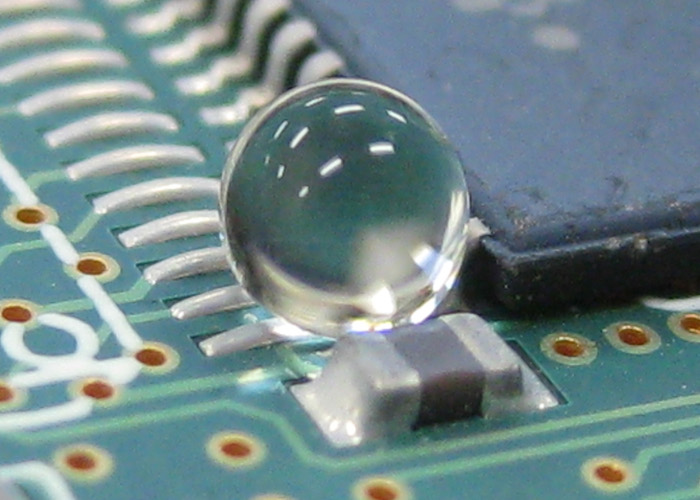

Finished Product

Components emerge ready to perform under extreme conditions, protected for years to come.